Sarnia, Ontario, Canada — Novel outdoor equipment shelters from Intertec Instrumentation have been chosen to help a European chemical manufacturer to upgrade its distributed plant control system.

Constructed using unique composite GRP (glass fiber reinforced polyester) materials, four Intertec shelters will provide advanced fire resistance properties. This attribute will simplify the housing and protection of electronic control and instrumentation equipment at optimized satellite locations within the processing plant.

Additionally, the GRP-based fabrication materials significantly reduces the weight of the shelters compared with traditional metal- or concrete-based constructions. In this application, this weight reduction will allow the plant operator to further optimize the positioning of the control system by mounting three of the shelters at height on steelwork frames.

The shelters offer F60-rated passive fire resistance, providing a barrier to fire spread for 60 minutes. This is achieved by means of a unique composite material that combines GRP sheets with embedded layers of mineral wool.

The shelters provide large interior floor areas up to 55 m2 (5 x 11 m). To help speed this plant upgrade project, Intertec is providing the plant buildings fitted with lighting, a raised floor to accommodate cabling, and ducting for the cooling air with a sophisticated downflow cooling system to protect the electronics equipment.

Fire-Resistant Shelters Simplify Chemical Plant's Control System Upgrade

Novel outdoor equipment shelters from Intertec Instrumentation have been chosen to help a European chemical manufacturer to upgrade its distributed plant control system.

Dec 20, 2018

Latest in Products

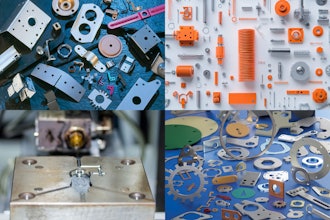

Made-to-Order Precision Stamped Components for Insert Molding

September 10, 2025

Fast Security Doors for Facility Exteriors

September 10, 2025

Eltwin Solid State Contactors

September 9, 2025