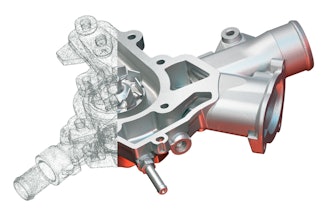

Cincinnati, OH — Clippard’s media isolation valves are solenoid-operated devices that use a flexible diaphragm to isolate the actuation mechanism from the fluid path. Media isolation valves are commonly used for a wide variety of applications, including those that require precise, repeatable dispensing of media.

All wetted areas of the valve are PTFE, making this series ideal for use with corrosive media.

A unique feature is the one-piece valve stem that functions as a sealing membrane while also supporting and centralizing the poppet in the seating area. This multi-functional poppet/diaphragm/stem results in a simplified design with fewer parts, longer life and zero dead volume.

These valves are highly modifiable with various mounting, porting, material, flow and voltage options. Industries and applications that commonly use these types of valves to isolate gas or liquid include: drug dispensing, laboratory equipment, analytical, chemical analysis, sampling, life science/ biotech, genetic research, gas chromatography, spectrometry, DNA synthesizing, blood analyzing, printing, diagnostic equipment, fermentation, water treatment and more. The valves are CE, RoHS compliant and made in the U.S.A. See here for more information.