AMADA WELD TECH, Inc. (Monrovia, CA) announced the release of the SIGMA LS Laser Micromachining Subsystem, a femtosecond laser-integrated module ideal for precision micromachining of metals and metal alloys, polymers, ceramics and glasses.

With its small form factor and integration-ready design, the SIGMA LS is ideal for:

- Machine builders

- System integrators

- Contract manufacturers

- Job shops

- R&D laboratories

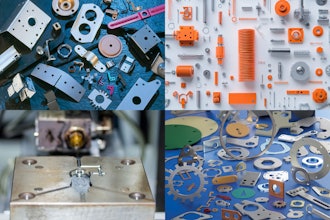

SIGMA LS offers processing solutions for a broad range of femtosecond laser micromachining applications requiring optimal quality, minimal thermal effects and high stability and dimensional accuracy including:

- Hole drilling in stainless steel cannula.

- Selective polymer ablation on metal.

- Hole drilling in ceramic microfluidics.

- Texturing metals, polymers and ceramics.

- Micromachining polymer filter screen.

- Micromachining metal struts and filaments.

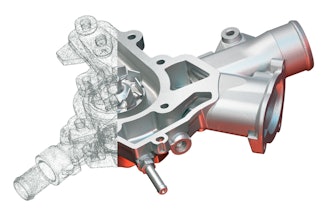

The ready-to-integrate subsystem features pre-installed sensitive laser and optical components, delivered with an optimized application and laser process.

AMADA WELD TECH provides on-site installation support and application training, as well as tooling and part handling guidance.

SIGMA LS is available with femtosecond laser options from 5 to 40 watts and both infrared (IR) and green wavelength options. Both air-cooled and water-cooled laser options are available.

Features include:

- Control panel for communications

- Sensitive optical components to prevent contamination

- Galvanometer scan head with multiple lens options for beam delivery

- Scanner and laser control software with a GUI tailored to the application

Also available are an optional fixed-optic focus head and on-axis (through-the-lens) and off-axis vision options. A rigid aluminum structure with a protective sheet metal enclosure ensures system robustness.