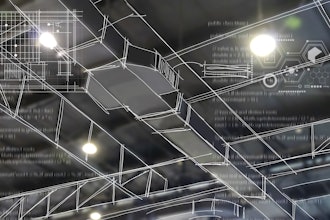

Northrop Grumman incorporated its digital ecosystem and advanced production capabilities in a recent demonstration to build wings for the Model 437 tech demonstrator flown by subsidiary Scaled Composites.

Development started in a fully-connected digital ecosystem with Northrop Grumman. Users from the customer and supplier collaborated to develop, analyze, build and test the wings ahead of the Model 437's first flight, which happened yesterday.

The Digital Pathfinder project demonstrated how the company's fully digital engineering ecosystem reduces engineering rework, accelerates schedule and reduces costs, offering advantages to customers on future aircraft programs.

Most Read on Design & Development Today:

- 3D Printed Breast Implants Could Be the Future of Plastic Surgery

- America's First Approved Gen IV Nuclear Reactor Is Under Construction

- Rocket Lab Fires its Archimedes Engine for the First Time

- LEO Flight Unveils Flying Car

By using real-world experiences gained on programs, including the B-21 Raider, the company continues to evolve its collaborative digital ecosystem, which connects the company, customers and supplier partners through the design, development and test phases on a variety of current and future programs.

The digital ecosystem cut engineering rework and redesign to less than one percent, compared to the 15% to 20% experienced using traditional methods. The demonstration also leveraged high-fidelity models combined with rigorous and approved model validation schemes to reduce requirements for ground and flight tests.

Looking forward, these models show the potential to significantly reduce the workload required to determine airworthiness, offering further cost and schedule savings opportunities.

Through Digital Pathfinder, Northrop Grumman’s high integrity digital thread connected engineers, customers and stakeholders in a virtual environment, allowing them to proactively foresee and solve the types of problems that typically plague acquisition programs up front and early — greatly improving program performance.

The demonstration also used advanced manufacturing techniques, including the production of a titanium structural bracket using plasma arc energy deposition. The application of this innovative additive manufacturing technique to form a titanium part is believed to be a first in the defense industry. At the same time, the Digital Pathfinder project applied advanced techniques to reduce the requirements for hard tooling while improving first time quality and reducing manufacturing rework.

Click here to subscribe to our daily newsletter featuring breaking design engineering industry news.