SKF and Amazon Web Services, Inc. (AWS), an Amazon.com, Inc. company, announced a collaboration to reinvent the field of industrial machine reliability and predictive maintenance with a joint solution.

The engagement will deliver an easy-to-use and easy-to-scale condition monitoring and analysis solution, making the ability to collect and analyze data using machine learning technologies available to a broader range of applications and customers.

SKF will combine its knowledge of rotating machinery and predictive maintenance with AWS's Industrial AI services that bring industrial expertise, AI and machine learning technologies together.

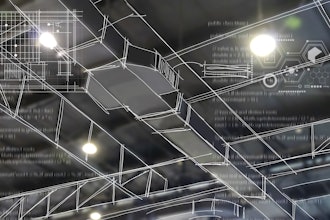

The product uses sensors, gateways and a machine learning service that is easy to install, commission and scale. SKF and AWS will also collaborate on the next generation of SKF's data analysis platform.

"The key to maximizing the business value of machine data lies in scale," said John Schmidt, President Industrial Region Americas of SKF. "With more condition monitoring tools available for a wider variety of their assets, end-users will gain more insights leading them to improved machine performance."

By adding this solution to its current portfolio of condition monitoring products, SKF will help large manufacturing sites increase the number of rotating assets in the end user's predictive maintenance programs by several thousand.

SKF's solution will provide these sites with machine alerts and alarms, enabling smarter, better decision making and more efficient maintenance planning and scheduling.

The same solution can also be utilized by entry-level users and small to mid-sized manufacturers, making the ability to use AI-driven analysis available to a larger portion of the industrial market segment.