Reusable containers are an economical and ecological way of moving products, but they are not without risk. Improperly handled and cleaned containers could harbor bacteria that might prompt a recall. Don't let this happen to you. There are simple ways to make your reusable containers safe.

Reusable Packaging Association's Guidelines for Suppliers

In 2015, the Reusable Packaging Association—RPA—issued guidelines for making plastic containers safer for reuse. Among the group's recommendations was for container suppliers to have a dedicated employee to ensure compliance with the Hazard Analysis and Critical Control Points, HACCP. The HACCP identifies and helps control microbe exposure to materials during the production process. Sanitation of the containers is a critical component of the process.

Storing and Transporting Containers Safely

The RPA offers several suggestions for those who use reusable plastic containers. Keep containers constantly covered, whether awaiting filling or during transport. This protects the containers from contamination from the elements. Interlocking or stacking the containers during storage also prevents collapse, which could cause contamination.

Package Labeling

The adhesive labels on reusable containers must come away cleanly. If it doesn't, the stickiness on the container could trap pathogens that might taint your supply. You will need to remove any glue residue left behind completely. The RPA designed a means to test adhesive labels used on reusable packages. To ensure that your labels won't leave behind a residue, only use those vetted by the RPA.

Reducing Weight of Reusable Containers

Though reusable packaging has economic advantages, it does have serious limitations. Many manufacturers are creating innovative ways to overcome these. Both the cost of producing reusable containers and their shipping weight make them more expensive than disposable containers. EcoPack weighs 50 percent less and costs up to 70 percent less than other containers. These reusable containers combine plastics and a sturdy design to solve the weight issue.

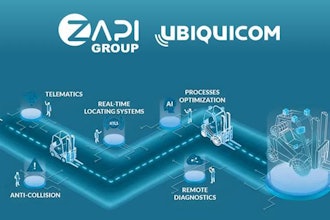

Improving Tracking

Another issue with reusable containers is the labor required to scan barcodes to track the use of the containers. Adding RFID transmitters allows for automated tracking, which makes loss less likely and makes reusable containers an even more economical alternative to disposable boxes. This could avoid the 5 to 15 percent error rate with human inventorying.

Preventing Cross-Contamination

Though reusable containers have never caused food-borne illness outbreaks, preventing cross-contamination is critical. Ensuring all components are sanitized and preventing containers from touching each other can prevent cross-contamination. Cross-contamination may also occur when setting containers on the ground. Avoid placing containers on unclean surfaces or allowing them to touch non-sanitized products. And never reuse uncleaned containers.

Avoiding Spoilage

Spoilage can occur with improperly cleaned containers that harbor bacteria that encourage food degradation. To avoid spoilage of the food stored in the containers, always use the correct storage temperature and provide adequate air flow. Additionally, you must use clean and sterilized containers every time. Otherwise, pathogens from the container could cause the food to spoil.

Cleaning and Sanitizing Containers

Containers require cleaning and sanitizing with each use. If you can no longer properly clean a container, discard it. Additionally, cleaning has four important components. You must have the proper concentration of the sanitizing agent. When sanitizing, use chlorine bleach diluted to between 50 and 200 ppm to adhere to USDA regulations. Additionally, you must expose it to the sanitizer for the correct amount of time and at the right temperature. Scrubbing will also help completely clean the containers. Without all four, your containers may not be clean.

Testing for Pathogens

Yes, you must carefully maintain the cleanliness of your containers. But part of that is regular testing. Even the best cleaners can make mistakes. Because you don't have complete control over every part of the supply chain, you should test your containers as soon as you receive them from another facility. This ensures everyone at all steps of the process complies with sanitizing regulations for reusable containers.

Getting the Most from Your Reusable Containers

Reusable containers save you money and are better for the planet. But you need to maintain the containers to ensure their safety. Thanks to the RPA, you have a set of industry-created guidelines to help you. By following these rules, you'll avoid the nightmare of recalls caused by unsanitary conditions.

Megan Ray Nichols is a STEM writer and blogger.