One of highest areas of energy consumption for electric motors is the start-up cycle, as accelerating up to the necessary speed requires a lot of power. Soft starters and VSDs are great ways to reduce and manage energy usage during these periods, by reducing stresses on motors through optimizing start-ups and controlling speeds.

While both technologies can reduce consumption, each is better suited to specific areas. So, which technology is best?

Soft Starters

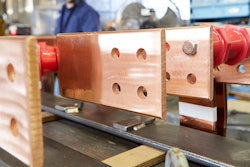

Soft starters are solid-state devices used to limit the amount of current that can inrush into a motor. The device then slowly lets in increasing amounts of current, softly ramping up the speed of the drive, allowing for a gradual start. This steady approach to power protects the motor from torque spikes and sudden tension, reducing wear and tear of the system.

Many conveyor belts use soft starters to steadily adjust torque to the necessary level. Without this control, sudden tensions could deteriorate the belt and cause it to snap due to mechanical stress. Naturally, this unexpected failure could lead to delays in production.

As the name implies, soft starters only affect the start-up and stopping processes of equipment. While managing this process does improve the energy consumption typically associated with powering up machinery, it does not help control energy consumption during operations.

Soft starters are not expensive devices, and their easy implementation enables manufacturers to improve energy efficiency with very little investment. They are less invasive than other options and as they are a solid state—there are no parts to replace should the device require maintenance.

Soft starters are limited in the amount of money and energy they can save, primarily due to the fact they only influence the start-up and stopping processes of machinery. That said, some high-end soft starters can achieve up to 99 percent better energy efficiency, compared to normal start-up periods. To improve efficiency during machinery operations, a VSD could be a better option.

VSDs

Unlike soft starters, VSDs manage energy consumption by controlling the speed of a motor while it is powering a piece of machinery. VSDs work by converting input current into specific frequencies, with each frequency translating to a determined speed. VSDs not only help reduce consumption during start-up, but also give manufacturers total control of engine speed in all phases of the motor.

The control provided by a VSD also allows for higher quality of actuation to be achieved. More precise control can reduce unexpected stress and strains on the system, allowing devices to last longer as cycles have less impact and wear.

Advanced VSDs are beginning to implement machine learning technology—a type of artificial intelligence (AI) that allows them to learn and automatically optimize their cycle. Investing in a VSD of this type can greatly increase potential savings.

So, what’s the catch?

Original equipment manufacturers (OEMs) have worked hard to reduce the size and price of VSDs. However, these devices are still significantly larger and more expensive than soft starters. As a result, investing in VSDs is not feasible for all manufacturers. In these instances, a soft starter could be a good place for manufacturers to begin their journey to energy efficiency.

Obsolete Sourcing

Adopting either of these technologies, manufacturers can improve energy efficiency, while also increasing the life cycle of machines through more controlled power management. However, that’s not to say machines—or these devices—won’t fail.

A common reason for VSD failure, for instance, is electro-mechanical wear on capacitors. VSDs rely on these capacitors to provide a smooth power output at varying levels of current. However, electrolytic capacitors have a limited lifespan and can age faster than dry components. This alone can be a cause of VSD failure—putting all that effort to improve energy efficiency to waste.

When failure does happen, there several options for manufacturers. For older or obsolete models of VSDs, it is worth establishing a relationship with a specialist supplier of industrial parts. EU Automation provides a single stop for all obsolete automation parts—including soft starters and VSDs.

Energy efficiency is at the forefront of manufacturers’ priorities. Due to the colossal energy consumption of electric motors, it is vital to install effective cost and energy-saving measures from the beginning of these devices’ operations.

Regardless of whether a manufacturer invests in a soft starter, or the heftier VSD —failure to have either of these technologies in place could be a grave energy efficiency mistake.

Jonathan Wilkins is the marketing director at industrial parts supplier EU Automation.