Users no longer have to settle for one-size-fits-all solutions to protect the bearings in valuable equipment.

Have you ever heard a high-pitched whine from an electric motor? Have you seen a bearing fail due to inadequate lubrication or contamination? How about a contact oil seal that has damaged your equipment? If so, chances are that a non-contact bearing isolator is available for your situation.

Bearing isolators are used to retain lubrication, exclude contamination, and extend the service life of the equipment in which they are installed. Multiple oil seals have long been used to protect bearings. Figure 1 depicts a typical configuration used to prevent lubrication egress and contamination ingress. Both functions, which require at least two, and in some cases three oil seals, can be performed by a single bearing isolator.

Early bearing isolators consisted of metallic components with simple pathways to act as dynamic sealing elements with O-rings to provide a static seal on the shaft and bore housing. Today’s bearing isolators are highly engineered seals with tight tolerances, intricate labyrinth pathways with abrupt directional changes, and special features for improved sealing (Figure 2).

Standard bearing isolators are used to prevent premature bearing failure due to condensation from daily wash downs, inadequate labyrinth excluder ring (LER) seals, and aggressive chemical attack. They are manufactured from a variety of materials depending upon the application requirements, including: size, temperature, the application itself, media, pressure, and speed (STAMPS). This information is required to determine the type of material that will be used, and any special features that are needed to adequately seal the application. If the sealing solution is based on inaccurate or incomplete information, there is a good chance it will fail.

Industry Standards

Industry standards are among the most limiting factors with regard to material requirements. For example, the American Petroleum Institute’s API 610 standard requires that all bearing isolators for the petroleum, heavy-duty chemical, and gas industries be made of non-sparking material. Although this standard applies strictly to these industries, it has been adopted by others as well. As a result, bronze is the most common material used in the manufacture of metallic bearing isolators. Even though it does not comply with the API 610 standard, the second most common material is stainless steel, used primarily in applications subject to FDA approval.

If a metallic bearing isolator is not mandatory, polytetrafluoroethylene (PTFE) mixtures can provide similar characteristics. PTFE can be used to make FDA-compliant and chemical-resistant bearing isolators. Although PTFE isolators are not as common as metallic ones, they are often a better solution depending on the application and equipment.

O-rings should also be considered in reviewing the application. Most manufacturers equip their standard bearing isolators with brown FKM O-rings. Depending on the application, O-rings made of PTFE-encapsulated FKM, AFLAS, or silicone can be specified instead. Improper material selection causes O-rings to be the first component to fail in the event of chemical attacks or extreme temperatures.

Size and temperature are often assumed to be enough information for a manufacturer to provide an effective sealing solution. Although both are important, the STAMPS data is needed to provide a viable bearing isolator for a particular application. Application data sheets help ensure all relevant data is collected, and should be completed for review by application and product design engineers.

Special Features

Special features for bearing isolators are a relatively new development in response to user demand. For most applications, either an oil seal or bearing isolator can be used. Conventional wisdom has it that contact lip seals prevent oil leaks or contamination ingress. However, bearing isolators perform the same functions and last five to seven times as long. In addition, they can now provide electrical sealing.

Electric induction motors controlled by pulse-width-modulation (PWM), variable-frequency drives (VFD) allow torque and horsepower to be adjusted to optimize both process parameters and energy requirements. This control provides instant savings in operating power, and enables electric motors designed to run at 100 rpm, to run at 60 rpm in order to reduce electric draw.

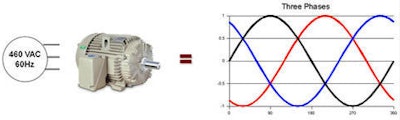

Uncontrolled electric induction motors are designed to run on a three-phase, sine-wave power scheme (Figure 3). The frequency, phase (120° apart), and amplitude of the input power are balanced so their sum at any point in time is equal to zero, thereby providing a balanced circuit.

When VFDs are used in electric induction motors, power is no longer provided in a balanced, three- phase sine curve, but in controlled pulses (Figure 4), referred to as square-wave or six-step voltage.

As this voltage is transferred to the motor, the variation in input power must be dissipated. The pulses create a capacitive-couple, common-mode voltage (CMV) on the motor shaft. This excess unbalanced voltage takes the path of least resistance to ground, which is most often through the bearings. Here, it exceeds the insulation levels of the oil film causing it to arc from the bearings’ inner to outer races. These voltage arcs act as tack welds on the outer races, and electrical discharge machining (EDM) pitting occurs thousands of times a second around the bearings, eventually resulting in failure from fluting damage (Figure 5). This damage creates the high-pitched whine referred to earlier as the bearing elements roll over the fluted races, much like a car driving over rumble strips.

To address this problem, manufacturers have added conductive brushes to traditional bearing isolators to prevent stray voltage from passing through the bearings (Figure 6). This shaft-grounding feature acts as the path of least resistance for the voltage to travel to ground without fluting the bearings. The brushes dissipate any existing CMV from the shaft and prevent any future EDM from occurring. Note that once a bearing has been fluted, a shaft-grounding bearing isolator cannot reverse the damage.

A traditional bearing isolator can be used to provide additional dynamic sealing on the non-drive end of a motor. For larger and higher-power motors, most manufacturers recommend installing insulated bearings on the non-drive end to ensure all stray voltage is forced through the conductive brushes and delivered safely to ground.

Electrical sealing is just one of the challenges facing bearing isolator manufacturers. As noted, one of the primary functions of a bearing isolator is to exclude contamination. In many industries, such as mining, power generation, and primary metals, there are applications that are exposed to extremely dirty conditions. Typical lip seals last just three to six months in these environments, compared with up to three years for a bearing isolator. Coal pulverizers and mine cars, for example, prompted manufacturers to begin using air filters in their bearing isolators. These filters consist of a closed-cell foam to eliminate any contamination from entering the seal pathways (Figure 7). The foam is added to a groove within the bearing isolator to act as a self-cleaning, long-lasting filter, directing any contamination to a drain port.

Split oil seals have been used for many years to facilitate installation by eliminating the need to first disassemble the equipment. Bearing isolator manufacturers have also taken advantage of split designs, albeit with some restrictions that do not apply to traditional isolators. Non-metallic, flooded, and hybrid bearing isolators, for example, cannot be split due to their material of construction and application parameters.

Traditional bearing isolators cannot be used in flooded applications, where the lubrication level is above the drain port. Otherwise, lubricant will travel through the labyrinth in the seal and leak out. Forced lubrication systems often cause traditional bearing isolators to leak, unless the system can be vented to the environment. It should be noted that the labyrinth paths in traditional bearing isolators are not designed to retain either positive or negative pressure. So, when pressure differentials occur, as in the case of forced lubrication systems, lubricant will leak through the labyrinth in a manner similar to flooded conditions.

Manufacturers have also solved this problem with a hybrid seal that is rated for conditions beyond the capabilities of traditional isolators. These flooded seals accommodate fully submerged lubrication levels and retain up to 7 psi of pressure, which is comparable to most general-purpose oil seals.

Industrial sealing applications are highly diverse, so bearing isolator manufacturers have to determine what type of isolators should be used on a case-by-case basis. In any event, users no longer have to settle for one-size-fits-all solutions to protecting the bearings in their valuable equipment.

For more information visit www.garlock.com.