Arizona Governor Doug Ducey and Paul Charles, President and CEO of American Battery Factory (ABF), announced that Tucson, Arizona has been selected as the site for the first in a planned series of battery cell gigafactories based in the U.S.

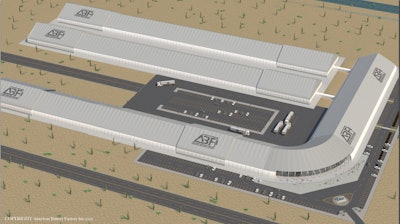

The site will serve as ABF’s official headquarters and will be the country’s largest gigafactory for the production of lithium iron phosphate (LFP) battery cells at approximately 2 million square feet, providing an estimated $1.2 billion in capital investment, $3.1 billion in economic impact to the state and accelerating the growth of the clean energy economy across the country.

Approximately 300 high-paying jobs will be provided in the first phase of the factory’s opening, scaling up to 1,000 cumulative jobs. Positions include operations, production, scientific and technology jobs including research and development, automation and robotics, executive and other headquarter positions.

Avoiding the use of nickel and cobalt, ABF’s materials are more ethically sourced and last more than double the average performance of other batteries, making them an ideal option for durable and dependable energy storage systems.

The cells will empower consumers, households, business owners and electric utilities to automate the management of their own inventory of power, gaining the independence to optimize and transform energy usage on their own terms. Energy storage made possible by ABF can power on-the-go lifestyles, off-the-grid living and industrial utilities as well as public industries and sectors.

To be located on 267 acres in Pima County’s renowned Aerospace Research Campus, ABF’s headquarters will be the home of energy storage innovation, with opportunities for new technology development.

Through rapid modular construction, the company plans to have the headquarters, R&D center and initial factory module built within the next 18 to 24 months. Using cutting-edge construction technology, the building will greatly limit waste at the site, be airtight and will ensure the protection of the battery cells during production.

With high-capacity border and transportation infrastructure, Tucson is an ideal fit for ABF’s vision and will provide the necessary access to ship battery cells to nearby markets.

ABF has secured strategic partnerships to make this landmark development a reality, partnering with Celgard (along with their parent company Asahi Kasei) for innovation and key cell components and Anovion for synthetic graphite. ABF plans to work with Honeywell to provide automation, cybersecurity and optimization products and services.