Early smoke detection is often critical to quickly suppress fires. In some settings such as manufacturing facilities, voluminous dust and particulates from various products and processes can be confused with smoke by most traditional, or passive, smoke detection systems, triggering ongoing alarms.

Resolving these alarms often requires excessive troubleshooting and maintenance to keep the system functional. When this is the case, prevalent nuisance alarms may compromise safety.

Although most manufacturing facilities deal with some level of dust, there is no more challenging environment that illustrates the need for advanced detection systems that accurately distinguish dust from smoke than inside a dust collection system. Fortunately, even within this dustiest of environments, aspirating smoke detection (ASD) technology can be an effective option.

According to Khaleel Rehman, director of development for Honeywell’s advanced detection fire team, advanced ASD systems can significantly reduce false alarms and maintenance while increasing safety by detecting smoke at the earliest possible stage via numerous sampling points.

The process draws in air through durable piping and analyzes it using sophisticated laser-based technology, imaging and photodiodes technology. Continuous air sampling drawn from the protected area through the pipe network to the sensing unit provides the fastest possible smoke detection rates.

In doing so, the system effectively distinguishes between actual smoke and dust or particulates to all but eliminate nuisance alarms. This core technology has been used for decades in sensitive applications such as cleanrooms and data centers where early smoke detection is critical.

Although these systems are quite flexible, many facilities use different processes and materials in varying volumes with unique facility layouts. It is important to consider engaging a partner that can design the system to fit a facility’s specific needs.

Extreme Dust: A Smoke Detection and Maintenance Challenge

In a manufacturing process at an aluminum tubing provider, a fine hot zinc powder is spray coated onto tubing in a spray booth area. The excess powder is then directed to a dust collection system consisting of large-diameter ducting and paper-based filter media before clean air is vented outdoors.

The zinc dust accumulates quickly and abundantly inside the ducting and can easily overwhelm the filters. This required excessive inspection and frequent maintenance to keep the system fully operational, according to Mike Angstadt, president of Palmetto, Florida-based Flagship Fire, Inc., whose company was hired to improve the system’s fire safety. The company provides special hazards fire suppression, control and detection solutions for unique, high value industrial assets.

Joseph Albert, project manager at Flagship Fire, Inc. notes, “When technicians would do routine maintenance every few months on sections of ducting, they would bang the sections with a rubber mallet to remove several inches of zinc dust that accumulated inside of this duct work.”

According to Angstadt, the dust laden, paper-based filter media would also periodically catch fire when ignited by a stray spark. The plant tasked Flagship Fire to improve smoke detection and fire safety within the dust collection system.

“Even though the deflagration index of the dust is low enough that providing explosion protection is not required, the plant sought greater safety with early smoke detection and fire suppression inside the dust collection system,” said Angstadt.

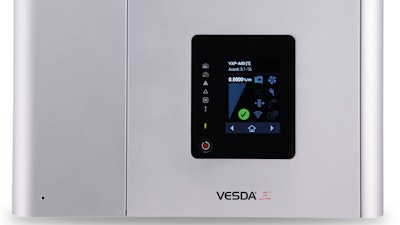

As a solution, Flagship Fire specified an ASD system called VESDA-E VEU by Honeywell, a global leader in fire and life safety products. The ASD system draws air samples in a continuous process through holes in durable industrial pipe mounted along the walls and ceiling.

The VESDA-E VEU analyzes the air in a flair detection chamber that uses a short wavelength laser, a CMOS imager and multiple photodiodes that can distinguish between smoke and dust, minimizing false alarms. The system is cross zoned with thermal detectors inside the dust collection filter area.

“With this arrangement, plant operators can manually discharge the high-pressure, CO2 fire suppression agent as needed or if an incident occurred after hours and no one was present, the plant’s VESDA system, cross zoned with a thermal device, will automatically discharge to suppress the fire,” said Angstadt.

Some minor adjustments were also required to increase system reliability. Since the ASD system draws in air, it does not require direct airflow into the analyzer. In fact, too much airflow could affect the results, so Flagship Fire angled the VESDA air sampling points away from the most voluminous air flow sources.

Flagship Fire also specified Schedule-40 galvanized VESDA pipe in the ductwork near the hot zinc spray coating area to withstand the heat to address the site’s needs.

According to Angstadt, the VESDA smoke detection system has performed well since the installation, in conjunction with the thermal device and automatic CO2 fire suppression system.

This arrangement has not only minimized false alarms caused by particulates in the dust collection system but also helped improved plant safety by enabling smoke detection at the earliest possible stages of a fire.

---

Del Williams is a Technical Writer who lives in Torrance, California.