In the material handling industry, every second counts, and facilities cannot afford to let precious time go to waste. Yet, downtime continues to plague intralogistics companies.

Threats to efficient operations abound, including low overall equipment effectiveness (OEE), high maintenance costs, and unpredictable machine availability. Advances in edge hardware and software—paired with cloud availability when needed—address these and other challenges, empowering companies to remain competitive and meet increasing market demands.

OEE Challenges

While the landscape is changing, many intralogistics companies lack the necessary means of managing automation equipment effectively, and tracking machine wear and patterns of inefficiencies, resulting in poor OEE. Addressing these issues requires a link between asset management and production, often missing from the traditional machine automation model.

As a result, companies are unable to predict downtime, creating a scramble to address issues when they arise. This reactive approach to maintenance—combined with myriad software, firmware, and program revisions strewn across equipment and devices on the facility floor—increases costs and downtime.

Further complicating matters, many end users in the intralogistics space restrict original equipment manufacturer (OEM) remote access to material handling equipment in their warehouses and fulfillment centers for security reasons, making it difficult for suppliers to guarantee uptime.

Industrial Edge Devices Securely Bridge OT and IT

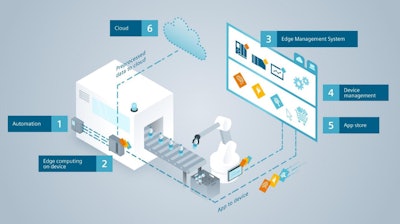

Industrial edge devices and software can integrate OT and IT in a managed environment, helping users to increase uptime and OEE. Edge devices communicate directly with PLCs and other devices on the facility floor, conditioning data for analysis and other IT applications (Figure 1, top).

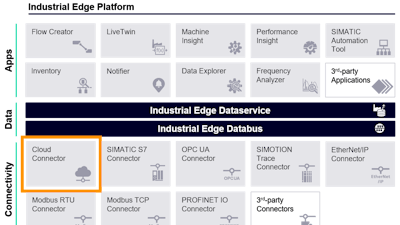

These devices natively run several edge apps, including AI-based predictive maintenance. For material handling, applications are available to monitor and assess performance of motors and drives, improving OEE through condition monitoring and issue identification, prior to failure and unplanned downtime. End users can run off-the-shelf applications (Figure 2), or they can leverage Docker, a set of platform as a service (PaaS) products, to create their own custom edge apps using high-level programming languages.

Figure 2: Off-the-shelf edge apps and connectivity options available using Siemens Industrial Edge.Siemens

Figure 2: Off-the-shelf edge apps and connectivity options available using Siemens Industrial Edge.Siemens

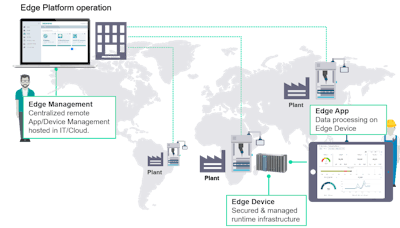

Additionally, modern edge management software enables OEMs to better support end users through access to machine diagnostic data, including future failure indications. This works in both cloud and on-premise deployments, through a central hub from which all edge devices are managed (Figure 3), placing a barrier between plant floor devices and the cloud to address cybersecurity issues.

Figure 3: Edge management centralizes system diagnostics and device and software version control.Siemens

Figure 3: Edge management centralizes system diagnostics and device and software version control.Siemens

An edge management system enables faster innovation cycles for developers and machine builders through centrally managed software, device, and security updates. Information is displayed via easy-to-understand dashboards out of the box, including system diagnostics. This central system can also be used to exchange data with a plant’s enterprise resource planning system.

In hybrid cloud-connected solutions, edge devices provide remote access to machine data, enable data pre-processing at the field level, and unlock further data analytics tools in the cloud.

In on-premise solutions, they keep data local, process data in onboard edge apps with minimal latency, and quickly provide results.

For the material handling industry, edge devices can detect and notify operations and engineering staff of operational issues, such as with conveyor drive trains. By flagging problematic conditions prior to equipment failure, opportunities are created to address issues during off-peak periods. This helps plant personnel identify spare parts, mitigating impacts of lengthy lead times.

Results

A manufacturer of stacker cranes created a machine monitoring dashboard in the Siemens Mindsphere cloud to display data from industrial edge devices. The dashboard displays utilization percentage, energy consumption, operation hours, drive and motor data, alarms, and other statistics in a user-selectable time range—helping users increase OEE.

Another manufacturer of conveyance systems implemented a belt slippage monitoring system by connecting sensors to the Siemens Industrial Edge system. Off-the-shelf apps identified and notified facility staff when belt slippage occurred, reducing the frequency of conveyor jams. Maintenance is performed using dashboard as a service through the edge device, reducing downtime.

Off-the-Shelf and Custom Tools Improve Efficiency

Edge devices and software are bringing IT capabilities to the field, even in situations where cloud connectivity is not possible or preferred, and industrial edge devices facilitate data analysis of field equipment, with optional cloud connectivity when desired.

With numerous off-the-shelf apps available and the ability to create custom apps leveraging Docker, planned maintenance is replacing unplanned downtime throughout the materials handling industry.

Colm Gavin is the Portfolio Development Manager for Siemens Digital Industries Software. For more information, visit www.sw.siemens.com.